Shop Floor Control

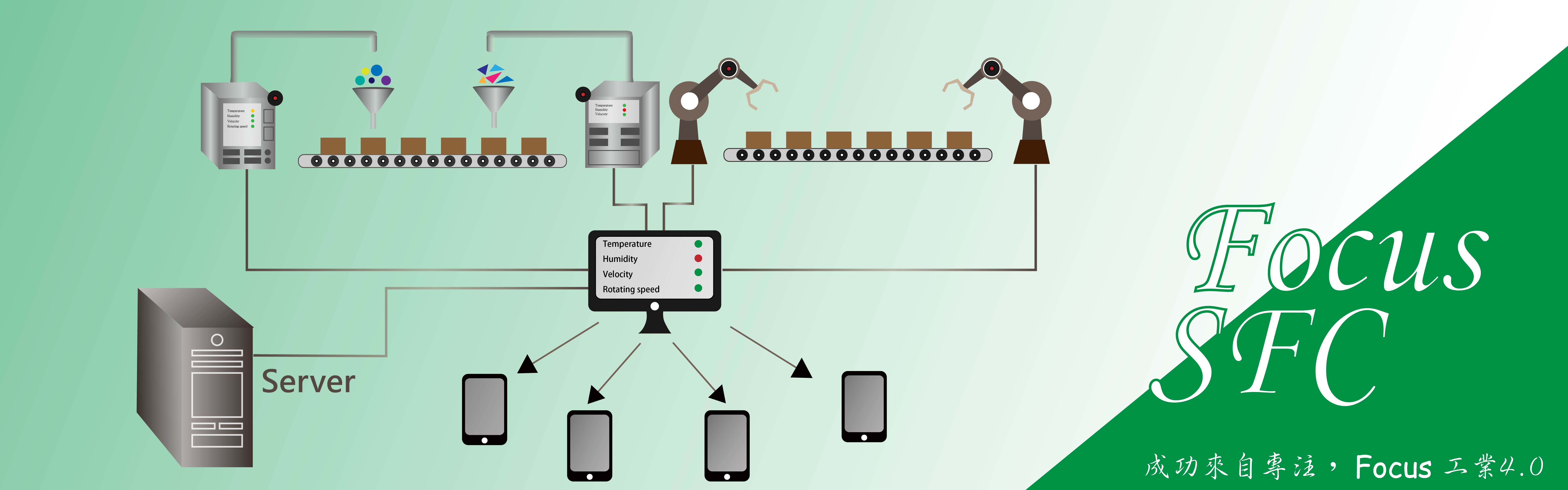

There are many small and medium-sized enterprises in Taiwan still use the computer and human brain to alternately manage the production of the factory with the advent of the era of automated production. The SFC (Shop Floor Control) system collects information through the Factory Data Collection, monitors manufacturing site and reports information to managers immediately so that the managers are able to realize the production status and make corresponding decisions to resolve production problems quickly, thus, it is help to reduce lost costs. Integrate computerized monitoring and automated information transmission to significantly reduce human error and personnel costs, and instantly and conveniently monitor the status of the production site.

◎ Features of Focus SFC

◆ Focus SFC offers the way of paperless operation that is more friendly for environments.

◆ Focus SFC is production line board management model.

√ Use tablets/cellphones/monitors multi-touch devices to realize the status of production immediately.

√ Simply install a single host to browse and operate simultaneously with multiple touch devices.

√ The combination of QR codes and boards simplify process and accelerate the conversation between internal staffs and production line staffs.

√ Achieve paperless production line through using multi-devices to manage images and files.

◆ Two-Tier routings design management

√ Supply two-tier process design. Manage material input, man-hour collection and progress return in first stage process.The second stage process is able to be the description of the process detail with ISO documents.

√ Simplify the process routing design. Dividing huge process into many stages can exactly manage the status of each section in production line.